Temporary Fire Services During Construction

Temporary Fire Services including hydrants, fire hose reels and extinguishers are a requirement of the National Construction Code. They provide protection against the potential risk of fire on a building site during construction. Refer clause E1.9 below for specific details.

On building sites, there is risk of fire from construction activities, materials and fuel.

This may pose a significant risk not only to people and the project but also to neighbouring properties.

It’s important to remember that a building site does not have the permanent fire protection systems that protect people and property when the building is complete.

A summary of the requirements can be found here.

What do I need to do from here?

As always, careful planning of the works is necessary. Ensure that this requirement is managed through design.

Then, during construction, implement the requirement in a timely manner to ensure a compliant fire protection system is in place as soon as possible, and before the limits are reached during construction.

All projects need to have a programme that considers the activities and timing required to ensure compliance. Please ensure lead time works including boundary connections, procurement etc are included and a milestone linked to the E1.9 criteria are included.

Keep in mind boundary connections are usually a long process and may impact on permanent water sources for example, so temporary services may be necessary as an interim, where approved by the relevant authorities/designers.

Ensure consideration is given to any water tanks and fire pumps that are required to maintain the fire services protection at all times.

Please ensure safety audits include for regular checking for compliance of these requirements.

If there are any issues with achieving strict compliance, consult the Building Certifier/Building Surveyor/PCA, and any relevant Regulators and Fire Brigades to ensure the works don’t progress without suitable fire protection.

| Check the relevant state legislation for more information: | ||

|---|---|---|

| QBCC – 2018/19 Compliance and Enforcement Strategy | ||

| QBCC – 2017 Contractual Obligations, Demerit Points and Bans | ||

| QBCC – Defective Work & Disputes | ||

| VBA – Compliance & Enforcement | ||

| VBA – Performance Audits | ||

| NSW – Licence Holder Overview |

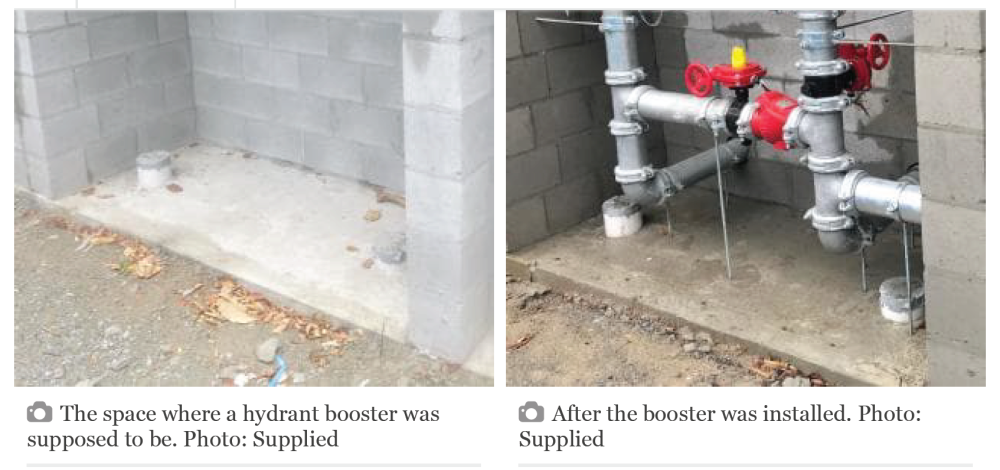

Non-compliant Site

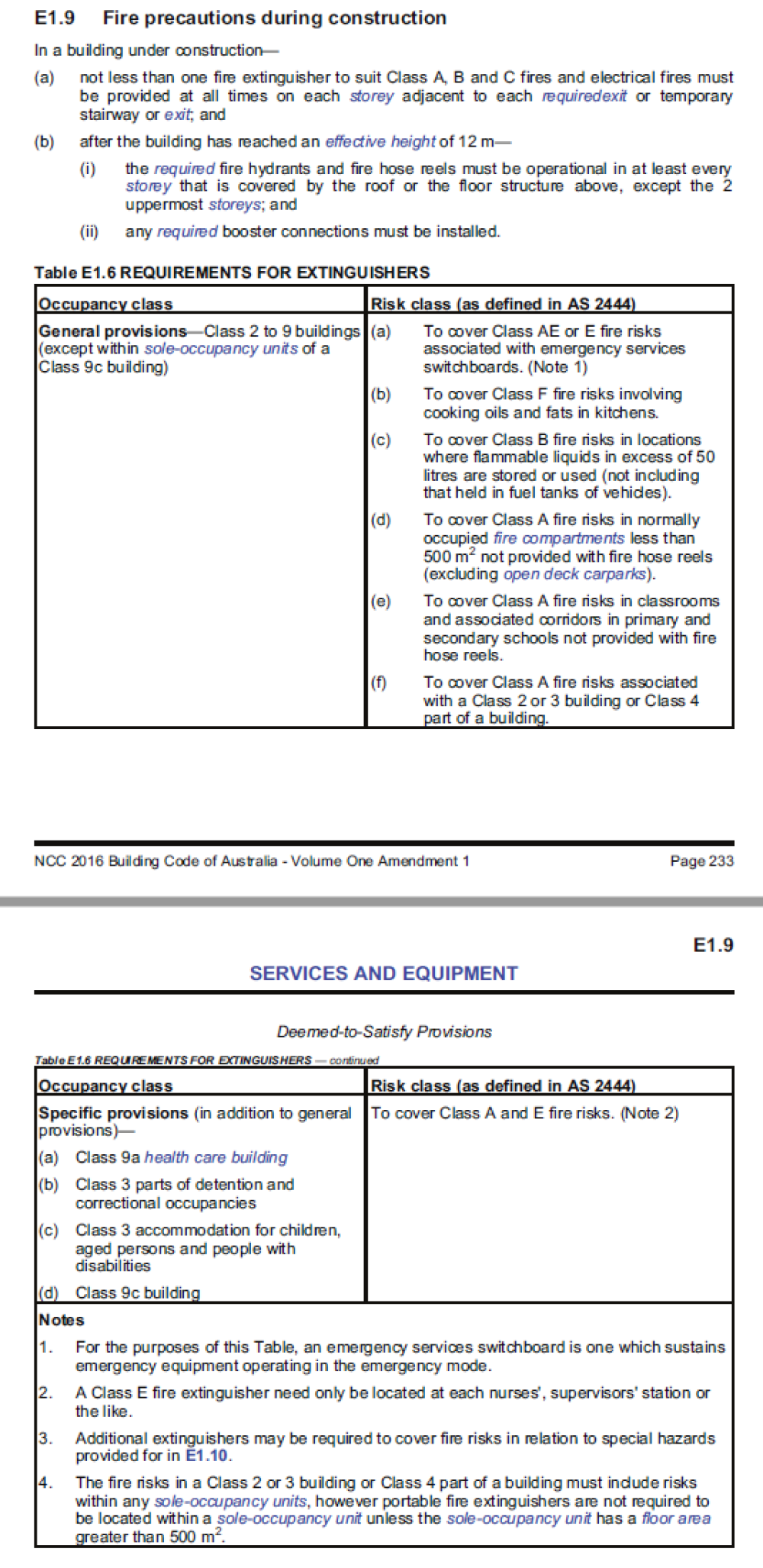

Compliant Site

Non-compliant (left) and compliant (right) temporary hydrant works

Valve Sets & Suction Lines

| NCC 2016 Amendment 1 Full Document | NCC 2019 Volume One Volume Two Volume Three |