Awareness, education and preparedness are the key factors in recognising and countering the potential risk to health of workers when working in hot environments.

What is Heat Related Illness?

Heat related illnesses occur when heat builds up in the body faster than the body can lose it. Excess body heat can occur when a person is exposed to extremes of temperature and humidity, and when generated from exertion or physical activity.

Factors that may contribute to heat related illnesses:

- the temperature/humidity and movement of the surrounding air

- the type and duration of work activity

- an persons physical condition, in particular when not acclimatised to conditions and/or activity

- insufficient hydration

- medical conditions (hypertension, diabetes) and some medications and substances.

How do we recognise the symptoms?

Heat related illness can range from mild heat rash or cramps through to heat exhaustion.

Some of the key warning signs include:

- muscles spasms or cramps

- heavy sweating in the early stages, and in the latter stages no sweating at all

- abnormal displays of confusion

- slurred speech

- blurred vision dizziness or fainting.

What can we do about it?

Reducing the onset of a heat related illness can be achieved by applying the following considerations;

- rescheduling work so the hot tasks are performed during the cooler part of the day;

- where possible, reducing the time spent doing hot tasks (for example, by job rotation);

- where possible, arranging for more Workers to do the job;

- providing extra rest breaks in a cool area;

- providing cool drinking water and ice (machines) near the work site.

- increasing air movement by fans or coolers

- installing shade cloth to reduce radiant heat from the sun

- giving consideration to working an eight hour day

- Educating Workers with respect to hydration and heat and fatigue management.

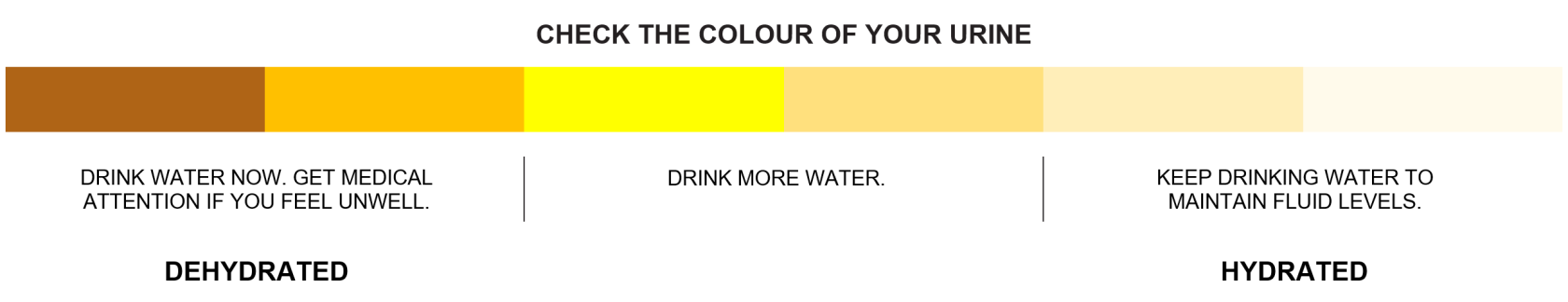

The following ‘Hydration Chart’ is a quick and easy way for workers to monitor their hydration level as one process in the steps to avoiding heat related illness. These Hydration Charts should be placed in site toilet and other prominent locations as prompts for all workers.

Outcome

Through the application of this safety alert workers should be able to monitor themselves and their mates whilst working in hot conditions and avoid unnecessary injury or illness as a result of the hot weather conditions.

What do we do in Extreme Hot Weather

Where the temperature reaches 35oC there will be an orderly cessation of work and preparations for the safe completion of critical task that are underway and/or applicable modifications to the workload.

Where the temperature is 28oC and the relative humidity is 75% or more after three hours from the commencement of a shift there will be an orderly cessation of work and preparations for the safe completion of critical task that are underway and/or applicable modifications to the workload.

If there are areas of the workplace that are below these climatic conditions work shall continue as normal in those areas. Employees unable to work elsewhere may be transferred to these areas if work is available. Employees may walk a reasonable distance through the open to and from amenities, provided it does not pose an imminent risk to their health or safety. The primary objective is to ensure that there is no reasonable concern for risk to the health or safety of an Employee undertaking the work.

The onset of these climatic conditions is the trigger to implement Heat Management controls and to redeploy workers to other areas of the site that is not impacted to the extent of the temperature and humidity guidelines. Extreme hot weather shall be measured on site by a temperature gauge which is compliant to the relevant Australian Standards and shall be undertaken in accordance with the manufacturers operating instructions and/or BOM weather station. There are a number of appropriate temperature gauges that meet this criteria, of which the Wet Bulb device is one.